For biology

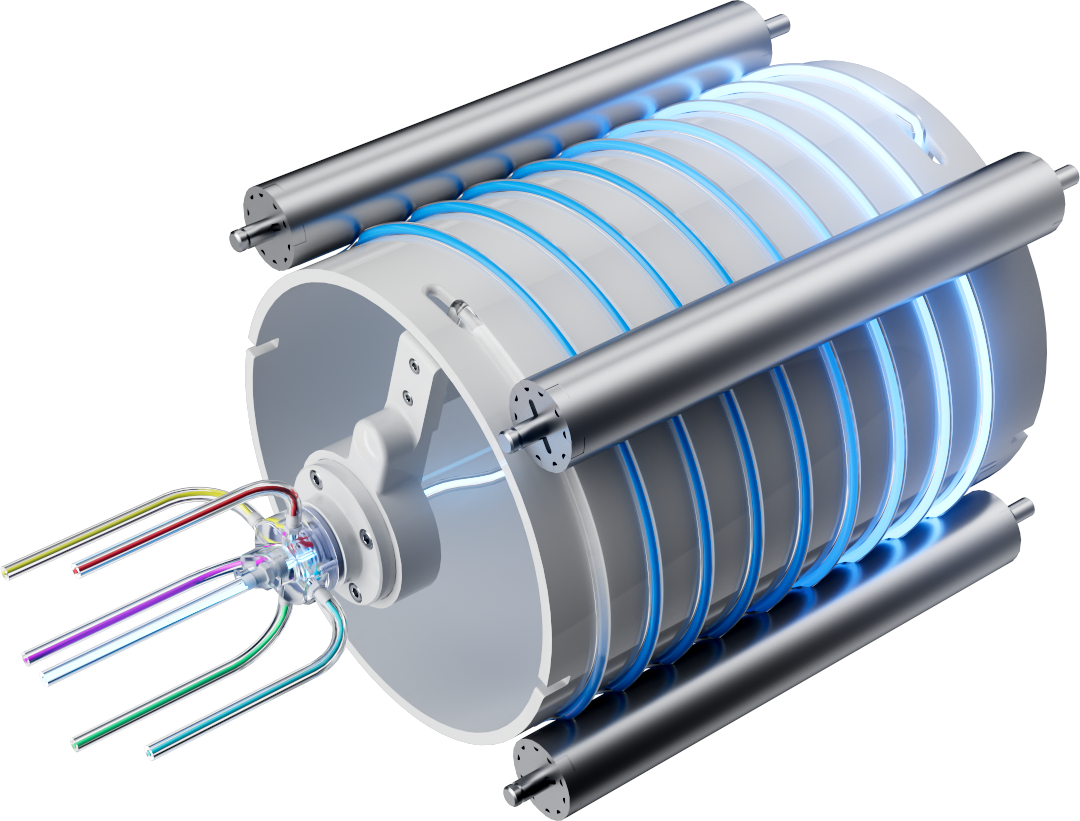

The life science industry is still largely reliant on batch manufacturing, which creates massive scalability hurdles, introduces variability in quality, and drives costs to unsustainable levels. Current options for continuous reactors are limited — some face scalability challenges, while others depend on carrier fluids that add unwanted complexity, validation burden, and downstream separation steps.

For chemistry

Industrial chemistry also struggles with batch-based limitations. Large-volume processes pose safety risks — exothermic reactions can run away or even explode. Beyond safety, batch production also creates challenges with quality, overhead, and control over reaction conditions. ReelReactor’s micro-batch approach makes reactions more predictable, controlled, and inherently safer, while reducing operational complexity.